|

Ningbo Xionghai Magnetics Co., Ltd.

|

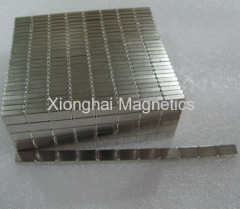

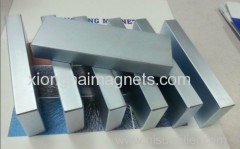

Grade N40 Epoxy Block NdFeB Rare Earth Magnets size:4X4X4mm for sale

| Price: | 0.01~20.0 USD |

| Payment Terms: | T/T,L/C;paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Neodymium magnets are the world's strongest magnets.

The material grade from N35 to 33AH.

Coatings: Ni, Ni-Cu-Ni, Zn, white-blue Zn, Epoxy, Gold.

Xionghai magnet preparesits anisotropic powders by either casting an alloy melt into a mold, or strip casing. Strip Casting offers the advantage of better chemical stability. Subsequently, the ingot from the mold or the flakes from Strip Casting are pulverized to a uniform grain/particle size. The best method for obtaining the desired grain size is by HDDR. The HDDR [hydrogenation-decomposition-desorption-recombination] process yields a more homogenous particle size with a minimum of α-Fe, and Nd-rich phases. Anisotropic Nd-Fe-B, HDDR powders prepared from strip cast alloys are used for the HAST [Highly Accelerated Stress Test] grades of NdFeB Magnets, including N, H, SH, UH, EH, and AH grades.

Neodymium magnets are the world's strongest magnets. All magnets are not created equal! Applied Magnets offers the highest quality neodymium magnets with consistent performance at lowest price. Our strong neodymium magnets are designed & manufactured to meet stringent quality standards using the latest technology. Neodymium magnets (also known as Neo, NdFeB, NIB or super magnets) , a type of rare earth magnets, are the permanent magnets made from neodymium, iron, boron and other minor elements. Strong Neodymium Magnets N50, stronger than N48, N45, N42, N40, N38 and N35. BrMax: 14500 gauss. Nickel-Copper-Nickel triple layer coated for maximum neodymium magnets durability and protection again corrosion. Contact us for neodymium magnets N50 wholesale Discount.

Neodymium magnets are the world's strongest magnets. All magnets are not created equal! Applied Magnets offers the highest quality neodymium magnets with consistent performance at lowest price. Our strong neodymium magnets are designed & manufactured to meet stringent quality standards using the latest technology. Neodymium magnets (also known as Neo, NdFeB, NIB or super magnets) , a type of rare earth magnets, are the permanent magnets made from neodymium, iron, boron and other minor elements. Strong Neodymium Magnets N50, stronger than N48, N45, N42, N40, N38 and N35. BrMax: 14500 gauss. Nickel-Copper-Nickel triple layer coated for maximum neodymium magnets durability and protection again corrosion. Contact us for neodymium magnets N50 wholesale Discount.

Improved Corrosion Resistance:

The HAST protocol used on our neodymium iron boron magnets can qualitatively reflect the service life of the magnet. This test exposes the magnet to 130°C, 95% RH, at 2 ATM for more than one day. The magnet is massed before and after the test. Our magnets measure a weight loss of less than 5 mg/cm2.

The HAST protocol used on our neodymium iron boron magnets can qualitatively reflect the service life of the magnet. This test exposes the magnet to 130°C, 95% RH, at 2 ATM for more than one day. The magnet is massed before and after the test. Our magnets measure a weight loss of less than 5 mg/cm2.

High Maximum Working Temperature:

Our AH series of NdFeB magnets have working temperatures up to 240°C.

Excellent Corrosion Resistance:

Xionghai magnet offers a number of coatings including: Nickel, Epoxy, Zinc, Tin, Phosphate, polypropylene etc.

Good Surface Tension and adhesion:

Adhesives require a properly prepared surface for bonding. Good wet-ability is one of the keys to good bonding. The shear strength for our Ni Plated magnets is greater than competitive magnets.

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Magnet Neodyme:

Neodymium rod magnet has been presented above, want more similar products, please click Neodymium disc magnet,ndfeb cylinder magnet,neodymium rod magnet.

Pictures of Neodymium Block Magnet / Sintered NdFeB magnet / Neodymium Iron Boron Magnet / Sehr Starke Magnet:

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Magnet Neodyme:

| Parameters | Units | Indicators |

| Density | g/cm³ | ≥7.3 |

| Home temperature | ℃ | 310-340 |

| BrReversible temperature coefficient | ℃/% | -0.100~-0.130 |

| HcjReversible temperature coefficient | ℃/% | 0.40~0.70 |

| Compressive strength | N/mm2 | 1050 |

| Bending strength | N/mm2 | 250 |

| Tensile strength | N/mm2 | 80 |

| Webster Hardness | 600 | |

| Coefficient of thermal expansion(20 to 200℃) | 10-6/k | ∥5⊥-1.5 |

| Specific heat | J/(Kg.K) | 460 |

| Thermal conductivity | W/(m.K) | 9 |

| Resistivity | μΩ.cm | 150 |

Process of sintered NdFeB magnets

Neodymium rod magnet has been presented above, want more similar products, please click Neodymium disc magnet,ndfeb cylinder magnet,neodymium rod magnet.

Pictures of Neodymium Block Magnet / Sintered NdFeB magnet / Neodymium Iron Boron Magnet / Sehr Starke Magnet:

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rare Earth Magnets Epoxy

Ndfeb Rare Earth Magnet

Rare Earth Ndfeb Magnet

Rare Earth Ndfeb

Rare Earth Magnets Disc

Rare Earth Disc Magnets

More>>