|

Ningbo Xionghai Magnetics Co., Ltd.

|

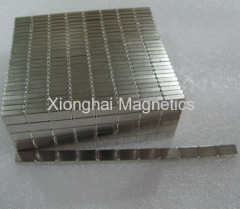

Rare Earth N42 Nickel Neodymium Block Magnets 12X6X4-D3mm

| Price: | 0.01~20.0 USD |

| Payment Terms: | T/T,L/C;paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Our neodymium block magnets are mainly used in MRI equipment and liner motor. The material grade from N35 to 33AH.

Block Magnet is one regular shape

Xionghai magnets preparesits anisotropic powders by either casting an alloy melt into a mold, or strip casing. Strip Casting offers the advantage of better chemical stability. Subsequently, the ingot from the mold or the flakes from Strip Casting are pulverized to a uniform grain/particle size. The best method for obtaining the desired grain size is by HDDR. The HDDR [hydrogenation-decomposition-desorption-recombination] process yields a more homogenous particle size with a minimum of α-Fe, and Nd-rich phases. Anisotropic Nd-Fe-B, HDDR powders prepared from strip cast alloys are used for the HAST [Highly Accelerated Stress Test] grades of NdFeB Magnets, including N, H, SH, UH, EH, and AH grades.

Rare earth neodymium magnets made by Applied Magnets are composed of top quality Neodymium, Iron, Boron raw materials, they have excellent magnetic property and extremely strong for its small size. rare earth neodymium magnets are the strongest types of permanent magnets. They have highest maximum energy product among all permanent magnets. The corrosion resistant nickel copper nickel triple layer coating provides smooth and shiny silver finish. ISO Certified, top notch quality guaranteed. Made of commercial grade, highest quality rare earth material. These magnets are very powerful, make sure you read safety warning before purchase. Our magnets are designed and manufactured to meet or exceed the highest quality standard, applications include fasteners, magnetic water treatment, wind generators therapy, speakers, motors, loudspeakers, hard disk drives, jewelry, science experiments, art, craft and much more. Neodymium magnets are powerful and fragile, they can be stuck together easily and pinch your fingers if you are not careful, they can get chipped or broken in a collision. Please read neodymium magnet safety information in "Seller Help" section before you order or use the magnets.

Block Magnet is one regular shape of Rare earth magnets and perment magnets.

It is always manufactured via Cutting and grinding etc .Block magnets or Rectangle magnets have the following important factors such as, Length,Width, Thickness, Round Edge etc.

Rare earth neodymium magnets made by Applied Magnets are composed of top quality Neodymium, Iron, Boron raw materials, they have excellent magnetic property and extremely strong for its small size. rare earth neodymium magnets are the strongest types of permanent magnets. They have highest maximum energy product among all permanent magnets. The corrosion resistant nickel copper nickel triple layer coating provides smooth and shiny silver finish. ISO Certified, top notch quality guaranteed. Made of commercial grade, highest quality rare earth material. These magnets are very powerful, make sure you read safety warning before purchase. Our magnets are designed and manufactured to meet or exceed the highest quality standard, applications include fasteners, magnetic water treatment, wind generators therapy, speakers, motors, loudspeakers, hard disk drives, jewelry, science experiments, art, craft and much more. Neodymium magnets are powerful and fragile, they can be stuck together easily and pinch your fingers if you are not careful, they can get chipped or broken in a collision. Please read neodymium magnet safety information in "Seller Help" section before you order or use the magnets.

Block Magnet is one regular shape of Rare earth magnets and perment magnets.

It is always manufactured via Cutting and grinding etc .Block magnets or Rectangle magnets have the following important factors such as, Length,Width, Thickness, Round Edge etc.

Our neodymium block magnets are mainly used in MRI equipment and liner motor.

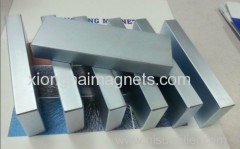

With our advanced equipment like hydrogen decrepition frunance and continuous sintering furnace, we can mass produce high grade like N52, 48H, 45SH, 40UH,33AH etc.

Also with our experience in material preparation and machining, we can produce very big block, such as 4" or 2" length.

We are also expert for packaging and transporting the high energy big block neo magnets.

We are also expert for packaging and transporting the high energy big block neo magnets.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rare Earth Neodymium

Rare Earth Magnets Disc

Rare Earth Disc Magnets

Rare Earth Lifting Magnets

Rare Earth Magnets Sphere

Rare Earth Magnets Epoxy

More>>