|

Ningbo Xionghai Magnetics Co., Ltd.

|

sintered Rare earth NdFeB magnet

| Price: | 0.01~20.0 USD |

| Payment Terms: | T/T,L/C;NdFeB Magnets |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

NdFeB Magnets.

Sizes: according to your requirements

Shapes: disc, cylinder, sphere, block ,ring ,tile, arc, and etc.

Coatings: Ni-Cu-Ni,Zn,Epoxy.

NdFeB Magnets are dark gray alloy. They are composed of Neodymium, Iron and Boron. Density of Neodymium magnets is .27Lb/in3 (7.5g/cm3).

Neodymium magnets are manufactured in a metallurgy process through alloying, crushing, powdering, pressing w/magnetic orientation, sintering, then cutting, coating, inspecting and packing before shipment.

Neodymium magnets offer the highest (BH)max and high Hci

(BH)max, the Maximum Energy Product, of Neodymium magnets is highest of any kind of permanent magnets today in the world. (BH)max at different grades of Neodymium magnets is 27 to 52 MGOe.

Neodymium magnets have extremely resistance to demagnetization with Hci, Intrisic coercive force, over 12,000 Oe.

Because of very high (BH)max and Hci, Neodymium magnets could be used as a reversible medium for large amount of energy transformation in miniaturized application where a strong magnetic demagnetization field exists , such as computer hard drive.

Armstrong Magnetics N40 Neodymium magnets in disk and rectangle shapes for customers' immediate needs and accept special orders for custom Neodymium magnets.

Neodymium magnets are most powerful of any kind of magnetic materials

Br of Neodymium magnets are much more than 11,000 Gauss. Therefore, Neodymium magnets have strong holding strength on metal surface and could be used as component for holding, separating, etc.

Neodymium magnets must be carefully handled to avoid personal injury and material damage due to its extremely magnetic strength and brittle property.

Neodymium magnets are sensitive to temperature change and even lose magnet properties at high temperature

Neodymium magnets lose -0.09 ~ -0.13% of Br/°C and can work stably under 80°C for low Hci Neodymium magnets and 150°C for high Hci Neodymium magnets.

Neodymium magnets are corrupted in humid environment

Surface protection is strongly recommended, such as plating, varnishing and encapsulating.

Neodymium magnets are hard and brittle

Neodymium magnets can be abrasively machined with coolant served to absorb heating and dust. Without coolant, rare earth magnets could crack and chip by the heat produced during high speed cutting or grinding, and the sparks contain the easily oxidized grinding dust that could cause fire!

Tolerance of Neodymium magnets

Unless otherwise specified, tolerance on dimension of magnetization is ±.005". Other dimensions are ±1.5% or ±.010", whichever is greater.

Xionghai magnet preparesits anisotropic powders by either casting an alloy melt into a mold, or strip casing. Strip Casting offers the advantage of better chemical stability. Subsequently, the ingot from the mold or the flakes from Strip Casting are pulverized to a uniform grain/particle size. The best method for obtaining the desired grain size is by HDDR. The HDDR [hydrogenation-decomposition-desorption-recombination] process yields a more homogenous particle size with a minimum of α-Fe, and Nd-rich phases. Anisotropic Nd-Fe-B, HDDR powders prepared from strip cast alloys are used for the HAST [Highly Accelerated Stress Test] grades of NdFeB Magnets, including N, H, SH, UH, EH, and AH grades.

Improved Corrosion Resistance:

The HAST protocol used on our neodymium iron boron magnets can qualitatively reflect the service life of the magnet. This test exposes the magnet to 130°C, 95% RH, at 2 ATM for more than one day. The magnet is massed before and after the test. Our magnets measure a weight loss of less than 5 mg/cm2.

High Maximum Working Temperature:

Our AH series of NdFeB magnets have working temperatures up to 240°C.

Applications: sensors, motors, rotors, wind turbine,wind generators, loudspeakers, magnetic hooks, filters automobiles, Toys, micro-special electric machinery, audio equipments, electronic industry, auto industry, magnetic transmission gears and magnet therapy equipment, sorption, ads, teaching tools and other office automation, magnet toys, aero generators, magnetic toys, magnetic separators, magnetic bracelets, magnetic necklaces, copiers, synchrotrons, radiation sources, free electron lasers, agriculture, detection earthquake, and so on.

The Magnetic Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Magnetic Properties of Sintered NdFeB Magnets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

| Parameters | Units | Indicators |

| Density | g/cm³ | ≥7.3 |

| Home temperature | ℃ | 310-340 |

| BrReversible temperature coefficient | ℃/% | -0.100~-0.130 |

| HcjReversible temperature coefficient | ℃/% | 0.40~0.70 |

| Compressive strength | N/mm2 | 1050 |

| Bending strength | N/mm2 | 250 |

| Tensile strength | N/mm2 | 80 |

| Webster Hardness | 600 | |

| Coefficient of thermal expansion(20 to 200℃) | 10-6/k | ∥5⊥-1.5 |

| Specific heat | J/(Kg.K) | 460 |

| Thermal conductivity | W/(m.K) | 9 |

| Resistivity | μΩ.cm | 150 |

The Surface Coatings of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Surface | Coating | thickness(um) | Coating Color | SST (hours) | PCT (hours) |

Nickel | Ni+Ni Ni+Cu+Ni | 10~20 | Bright Silvery | 24~72 | 24~72 |

Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | 48~96 | 48 |

Cr3+Zinc | Zn Cr-Zn | 5~8 | Bright Blue Shining Color | 16~48 36~72 | \ |

Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | 36~72 | 48 |

Au | Ni+Cu+Ni+Au | 10~25 | Gold | 12 | 48 |

Ag | Ni+Cu+Ni+Ag | 10~25 | Silver | 12 | 48 |

Epoxy | Epoxy Ni+Cu+Epoxy Zn+Epoxy | 10-20 15-30 15-25 | Black / Grey | 48 72~108 72~108 | |

Passivation | \ | 1-3 | Dark Grey | Temporary Protection | \ |

Phosphated | \ | 1-3 | Dark Grey | Temporary Protection | \ |

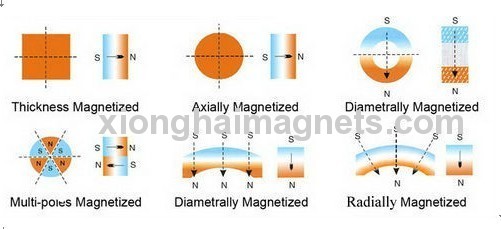

Magnetizing:

1.Thickness Magnetized

2.Axial magnetized

3.Diametral magnetized

4.Multi-poles magnetized

5.Radi al magnetized

.Common uses in different fields:

§ Security systems § Magnetic separators

§ Magnetic resonance imaging § Health bandages and plasters

§ Specialty door catches § Filters & strainers

§ Sensors § Speakers

§ Microphone/earphone § High performance motors

§ Brushless motor § Micromotor / servo motor

§ VCM(voice coil motor) § Automobiles

§ Magnetic coupling § Magnetic Chuck

§ Magnetic toy § Magnetic tools

Pictures of Neodymium RingMagnet / Sintered NdFeB magnet / Neodymium Iron Boron Magnet / Sehr Starke Magnete: