|

Ningbo Xionghai Magnetics Co., Ltd.

|

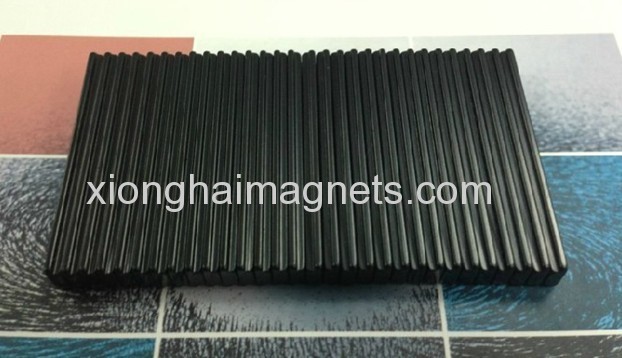

Nickle Irregular Magnet Rare Earth N48

| Price: | 0.01~20.0 USD |

| Payment Terms: | T/T,L/C;paypal |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Supplier Nickle planted Irregular Magnet.Nickel-Copper-Nickel Plated,super strong, high quality magnet . Magnet can be machinning into different shape

Neodymium magnets are dark gray alloy. They are composed of Neodymium, Iron and Boron. Density of Neodymium magnets is .27Lb/in3 (7.5g/cm3).

Neodymium magnets are manufactured in a metallurgy process through alloying, crushing, powdering, pressing w/magnetic orientation, sintering, then cutting, coating, inspecting and packing before shipment.

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Counter sunk hole NdFeB magnet

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Neodymium magnets are manufactured in a metallurgy process through alloying, crushing, powdering, pressing w/magnetic orientation, sintering, then cutting, coating, inspecting and packing before shipment.

Neodymium magnets offer the highest (BH)max and high Hci

(BH)max, the Maximum Energy Product, of Neodymium magnets is highest of any kind of permanent magnets today in the world. (BH)max at different grades of Neodymium magnets is 27 to 52 MGOe.

Neodymium magnets have extremely resistance to demagnetization with Hci, Intrisic coercive force, over 12,000 Oe.

Because of very high (BH)max and Hci, Neodymium magnets could be used as a reversible medium for large amount of energy transformation in miniaturized application where a strong magnetic demagnetization field exists , such as computer hard drive.

Armstrong Magnetics N40 Neodymium magnets in disk and rectangle shapes for customers' immediate needs and accept special orders for custom Neodymium magnets.

(BH)max, the Maximum Energy Product, of Neodymium magnets is highest of any kind of permanent magnets today in the world. (BH)max at different grades of Neodymium magnets is 27 to 52 MGOe.

Neodymium magnets have extremely resistance to demagnetization with Hci, Intrisic coercive force, over 12,000 Oe.

Because of very high (BH)max and Hci, Neodymium magnets could be used as a reversible medium for large amount of energy transformation in miniaturized application where a strong magnetic demagnetization field exists , such as computer hard drive.

Armstrong Magnetics N40 Neodymium magnets in disk and rectangle shapes for customers' immediate needs and accept special orders for custom Neodymium magnets.

Neodymium magnets are most powerful of any kind of magnetic materials

Br of Neodymium magnets are much more than 11,000 Gauss. Therefore, Neodymium magnets have strong holding strength on metal surface and could be used as component for holding, separating, etc.

Neodymium magnets must be carefully handled to avoid personal injury and material damage due to its extremely magnetic strength and brittle property.

Br of Neodymium magnets are much more than 11,000 Gauss. Therefore, Neodymium magnets have strong holding strength on metal surface and could be used as component for holding, separating, etc.

Neodymium magnets must be carefully handled to avoid personal injury and material damage due to its extremely magnetic strength and brittle property.

Neodymium magnets are sensitive to temperature change and even lose magnet properties at high temperature

Neodymium magnets lose -0.09 ~ -0.13% of Br/°C and can work stably under 80°C for low Hci Neodymium magnets and 150°C for high Hci Neodymium magnets.

Neodymium magnets lose -0.09 ~ -0.13% of Br/°C and can work stably under 80°C for low Hci Neodymium magnets and 150°C for high Hci Neodymium magnets.

Neodymium magnets are corrupted in humid environment

Surface protection is strongly recommended, such as plating, varnishing and encapsulating.

Surface protection is strongly recommended, such as plating, varnishing and encapsulating.

Neodymium magnets are hard and brittle

Neodymium magnets can be abrasively machined with coolant served to absorb heating and dust. Without coolant, rare earth magnets could crack and chip by the heat produced during high speed cutting or grinding, and the sparks contain the easily oxidized grinding dust that could cause fire!

Neodymium magnets can be abrasively machined with coolant served to absorb heating and dust. Without coolant, rare earth magnets could crack and chip by the heat produced during high speed cutting or grinding, and the sparks contain the easily oxidized grinding dust that could cause fire!

Tolerance of Neodymium magnets

Unless otherwise specified, tolerance on dimension of magnetization is ±.005". Other dimensions are ±1.5% or ±.010", whichever is greater.

Nickel-Copper-Nickel Plated ,super strong, high quality magnet . Magnet can be machinning into different shapes such as bread-shape , arc shape , T-shape ,triangle shape as long as you have demand.

Unless otherwise specified, tolerance on dimension of magnetization is ±.005". Other dimensions are ±1.5% or ±.010", whichever is greater.

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

| Parameters | Units | Indicators |

| Density | g/cm³ | ≥7.3 |

| Home temperature | ℃ | 310-340 |

| BrReversible temperature coefficient | ℃/% | -0.100~-0.130 |

| HcjReversible temperature coefficient | ℃/% | 0.40~0.70 |

| Compressive strength | N/mm2 | 1050 |

| Bending strength | N/mm2 | 250 |

| Tensile strength | N/mm2 | 80 |

| Webster Hardness | 600 | |

| Coefficient of thermal expansion(20 to 200℃) | 10-6/k | ∥5⊥-1.5 |

| Specific heat | J/(Kg.K) | 460 |

| Thermal conductivity | W/(m.K) | 9 |

| Resistivity | μΩ.cm | 150 |

Counter sunk hole NdFeB magnet

1. Materials: Rare earth Neodymium-Iron-Boron, Permanent Sintered Ndfeb Magnets;

2. Certification: ISO9001:2008;

3. Magnetic properties:

a) High coercive force,

b) (BH)max from 33 to 53MGOe,

c) Max working temperature up to 230°C;

4. Grades: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH, 30EH-35EH;

5. Shapes: Arc/Segment, or others;

6. Sizes: R x r x H x Degree, Customized;

7. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene and so on;

The Surface Coatings of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

The Surface Coatings of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Surface | Coating | thickness(um) | Coating Color | SST (hours) | PCT (hours) |

Nickel | Ni+Ni Ni+Cu+Ni | 10~20 | Bright Silvery | 24~72 | 24~72 |

Black Nickel | Ni+Cu+Ni | 10~20 | Bright Black | 48~96 | 48 |

Cr3+Zinc | Zn Cr-Zn | 5~8 | Bright Blue Shining Color | 16~48 36~72 | \ |

Sn | Ni+Cu+Ni+Sn | 10~25 | Silver | 36~72 | 48 |

Au | Ni+Cu+Ni+Au | 10~25 | Gold | 12 | 48 |

Ag | Ni+Cu+Ni+Ag | 10~25 | Silver | 12 | 48 |

Epoxy | Epoxy Ni+Cu+Epoxy Zn+Epoxy | 10-20 15-30 15-25 | Black / Grey | 48 72~108 72~108 | |

Passivation | \ | 1-3 | Dark Grey | Temporary Protection | \ |

Phosphated | \ | 1-3 | Dark Grey | Temporary Protection |

Applications: sensors, motors, rotors, wind turbine,wind generators, loudspeakers, magnetic hooks, filters automobiles, Toys, micro-special electric machinery, audio equipments, electronic industry, auto industry, magnetic transmission gears and magnet therapy equipment, sorption, ads, teaching tools and other office automation, magnet toys, aero generators, magnetic toys, magnetic separators, magnetic bracelets, magnetic necklaces, copiers, synchrotrons, radiation sources, free electron lasers, agriculture, detection earthquake, and so on.

Our magnetic bracelet is good in quality and competitive in price. We manufacture magnetic bracelet and supply OEM, ODM service according to your requirement.

If you want more detailed information of this product or related problems, please contact with us, we will reply as soon as possible (general in 24 hours).

Samples Pictures of Irregular Shaped Neodymium Super Magnets Neodimio Magneti Permanenti:

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Rare Earth Magnet

Ndfeb Rare Earth Magnet

Earth Rare Magnet

Smco Rare Earth Magnet

Alnico Rare Earth Magnet

Cobalt Rare Earth Magnet

More>>